Corrosion inhibitor compounds vaporize from the film. They are attracted to the charged surface of the metal by virtue of their polar orientation.

The VCI molecules align on the surface of the metal to a depth of 3 to 5 molecules. This layer of molecules passivates the charged surface and creates a barrier that prevents oxidation. The corrosion cell is unable to establish itself. Corrosion is stopped.

SicheR VCI is an additive that can be brought into most common packaging materials. Once exposed to air, the additive will dissolve into the air and dispose it self as a thin layer on metal surfaces. This layer blocks the access of humidity to the metal and the process of corrosion is prevented. The SicheR VCI technology is suitable for corrosion protection during shipment, temporary storage between manufacturing processes and mothballing of seldomly used equipment.

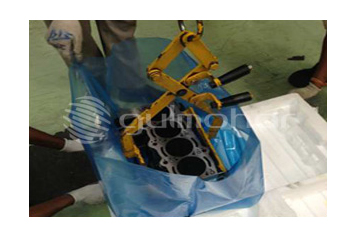

Corrosion protective Packaging is used when products have to be transported or stored for a certain period. The function of the corrosion protective packaging is to prevent corrosion without having to threat the metal with oil, grease, paint. SicheR VCI is compatible with most metals and alloys and also work with products consisting of parts made of different metals. SicheR VCI requires no grease or oil and no ore-treatment except ensuring that the metal surfaces are dry and clean. The metal product is placed in the SicheR VCI packaging material, which is closed and put into the transport packaging.